Do you need:

- A visual presentation for an exhibition?

- To see a selected part of your design work?

- To test a mini-series without getting into a mold?

To see a 3D model physically before the product has left the drawing board, will shorten development time dramatically by up to 20-50% compared to traditional development with various modifications of the mold.

A prototype provides the ideal starting point, because you early in the development process can visualize and evaluate the product along with other team members involved in the project, and everyone can see opportunities or limitations from their particular perspective of the project.

Materials

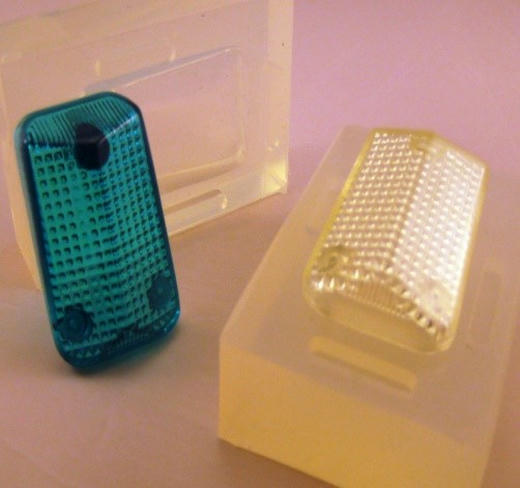

Plastic

The color of the parts in plastic is normally off white. You also have the option for transparent parts, if you have to evaluate for example a liquid within the part.

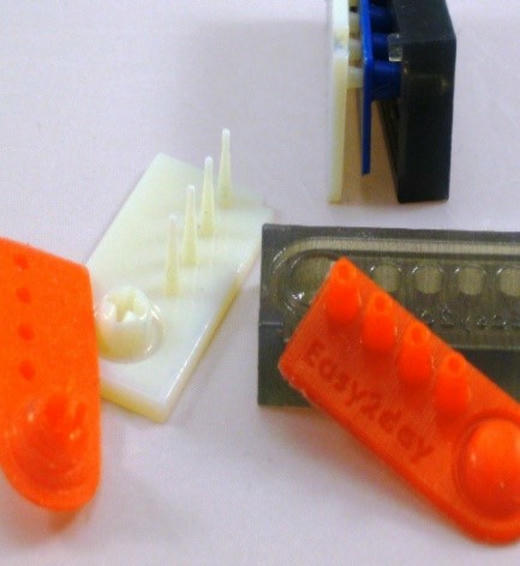

Rubber

If you want the prototype in flexible rubber material, you can choose between black and semi-transparent. You also have the possibility to combine plastic and rubber materials, so you thereby get completely new materials, which we call digital materials for prototypes.

Do you have other wishes, please call for an informal chat. Easy2day have the opportunity to offer many other processes linked to 3D models, and we will find an attractive solution for your project. The prototype you will have in your hand within a few days.

For request / price calculations on parts for prototypes, you can send files directly to Easy2day on the contact page.